Partners

Regional partners and experts in their fields have eagerly responded to the MIH’s call to implement a unique project aimed at preserving and enhancing the watchmaking heritage. These artisans, based in La Chaux-de-Fonds and its surroundings, have shown enthusiasm and pride in contributing their technical expertise to various aspects of the watch, resulting in a product of remarkable quality.

XJC / Xavier Perrenoud – Design

Xavier Perrenoud, the initiator of the previous two editions of the MIH Gaïa watch, once again brings his innovative vision to refresh contemporary aesthetics and watchmaking craftsmanship.

The celestial blue dial patterns are inspired by the visible formwork marks on the concrete walls of the MIH. These parallel and perpendicular lines also evoke the brutalist character of the building’s right angles.

Inspired by the Ensō, the Japanese term for “circle,” this symbol of Zen Buddhism draws attention to the emptiness it defines. This concept, also explored in contemporary art by Kengo Kita with his work Reconnecting, immerses us in a paradox: the duality and unity of a symbol that represents emptiness through a form.

In Kengo Kita’s work, circles become lines, and lines become circles, much like George Brodbeck’s dial. The interplay of solids and voids created by the random stops of the lines invites philosophical reflection on the balance of elements.

The choice of silver as a precious material, akin to concrete in contemporary architecture, allows for a subtle and elegant play of light through a minimalist aesthetic. The texture effects between the smooth surface of the dial and the raw appearance of the guilloché patterns echo the various volumes and textures of the building that MIH visitors can appreciate during their visit.

These curves balance the interlocking shapes of the circle and rectangle on the dial, with these pure forms directly inspired by the brutalist architecture.

XJC

Xavier Perrenoud, designer

The MIH Gaïa watch is a quite a unique project. What made you want to be a part of it?

“The fact that it is a collaborative project gives it a certain authenticity, transparency and logic in relation to the museum’s values. Today, the public wants to know the provenance of the products they buy, and this project is a window into the modern design of a horological piece.”

What positive impact do you think this project has as something “made in La Chaux-de-Fonds”?

“The MIH Gaïa is a way of highlighting one of the hubs of Swiss watchmaking – La Chaux-de-Fonds – and its expertise, as well as showcasing the local talent.”

Just like the MIH Gaïa watch, the design of a timepiece is always the result of a collaborative process. What are the differences, difficulties and benefits of working in this way?

“It’s always interesting to see a project mature and evolve in line with proposals from its participants. The design brief for the watch was to work from an original, pared-back display while taking inspiration from the MIH. Our thinking was focused on that goal, but right up until the end we were making changes. There were also certain constraints that pushed us to be original.”

What are the areas of activity, successes and expertise that can be attributed to your company?

“We specialise in providing creative direction for luxury brands and businesses focused on craftsmanship; our main priority is to work on the vision and the aesthetic unity which comes from that. Product design comes next and is closely linked to that first step.

Following an approach based on perpetual innovation, XJC has developed an “ideas laboratory” which explores different skills to create a piece. This allows us to invert the design process by not working from a commission. We could work from a particular technique, material, or form, for example.”

Sellita – the movement

Sellita has a long history in both the assembly and design and manufacture of quality automatic movements. One of its Swiss-made mechanical movements is at the heart of the MIH Gaïa watch, and was adapted to meet its requirements.

“The project is very exciting in its own right, as the watch is so elegant and beautiful. Through its originality, the MIH Gaïa watch presents a vision for watchmaking and a unique aesthetic that are perfectly in tune with the MIH’s values. The concept of a watch made entirely in La Chaux-de-Fonds is wonderful, and further reinforces the already very strong links between the city and the museum. This geographical connection really brings the project together and showcases the unique expertise we have in this city.”

Miguel Garcia, CEO

Sellita

Miguel Garcia, director

The MIH Gaïa watch is a quite a unique project. What made you want to be a part of it?

“First of all, it’s crucial to support our museum. “The MIH plays a central role in preserving and promoting the art of watchmaking. As a watchmaking business, the preservation of this heritage is obviously something particularly close to our hearts. And the project is very exciting in its own right, as the watch is so elegant and beautiful. Through its originality, the MIH Gaïa watch presents a unique vision for watchmaking and a unique aesthetic that are perfectly in tune with the MIH’s values.”

What positive impact do you think this project has as something “made in La Chaux-de-Fonds”?

“The concept of a watch made entirely in La Chaux-de-Fonds is wonderful, and further reinforces the already very strong links between the city and the museum. This geographical connection really brings the project together and showcases the unique expertise we have in this city. “

Just like the MIH Gaïa watch, the design of a timepiece is always the result of a collaborative process. What do you think are the differences, difficulties and benefits of working in this way?

“The MIH watch uses an original method of displaying time, based on discs. This may at first seem like a trivial decision, but it has major technical implications and requires great care in terms of developing the exterior and also assembling the watch.”

What are the areas of activity, successes and expertise that can be attributed to your company?

“Sellita was created in La Chaux-de-Fonds in 1950, and we have a long history in assembly as well as design and manufacture of quality mechanical movements. Over the years we have become an essential mainstay of the Swiss watchmaking industry. It therefore seemed a natural step that a Sellita movement would drive the MIH Gaïa watch.”

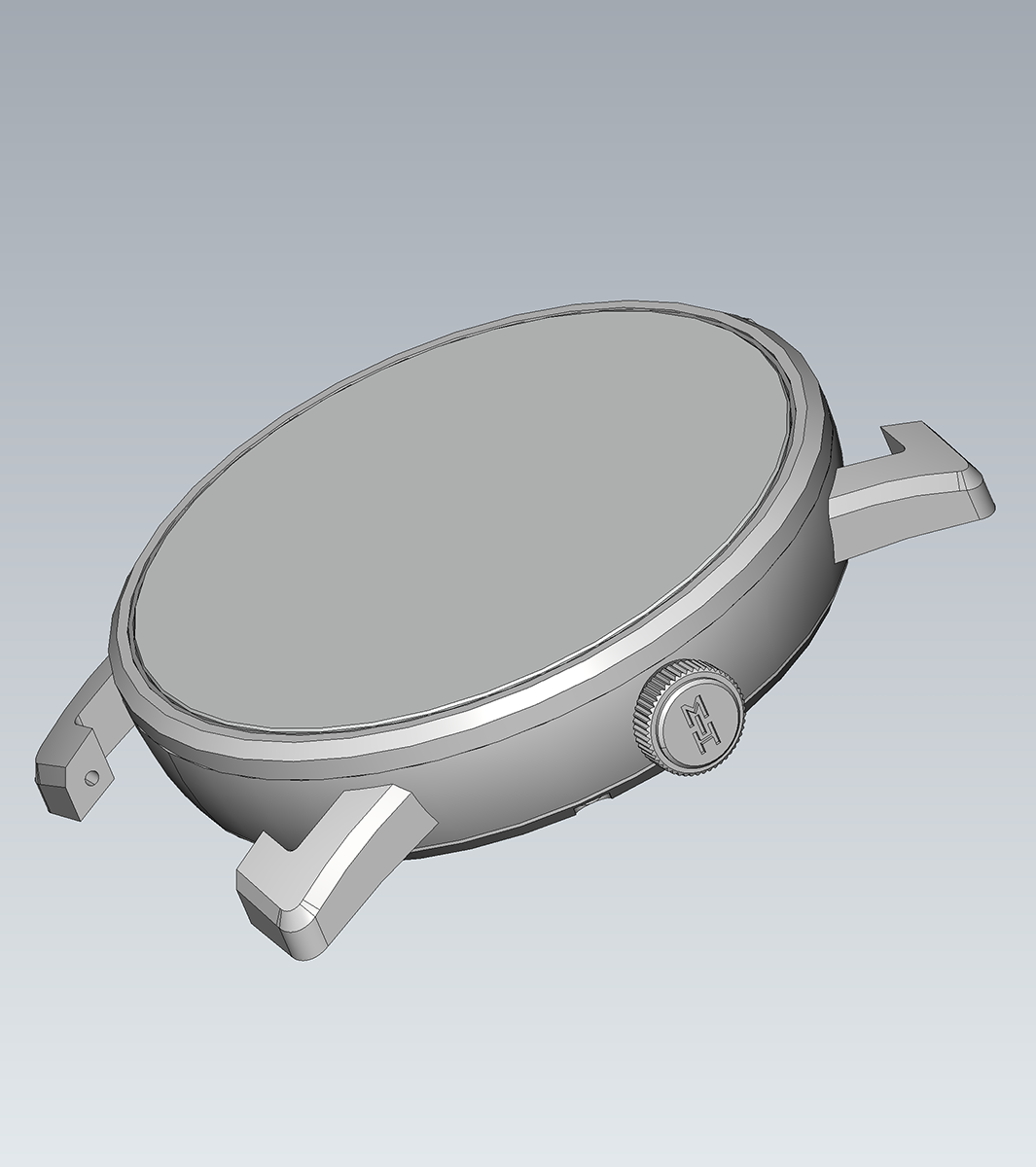

Stila – the case

The company Stila contributed their expertise to create the case for the watch. The result is a very finely crafted outer enclosure, demonstrating to collectors that the MIH Gaïa watch has a standard of workmanship on a par with the luxury watch brands.

Jean Singer & Cie – the dial

The manufacturer Jean Singer & Cie SA produces dials for the best-known watch brands. This family-run company offered the museum the full breadth of their experience in producing high-quality dials, in particular taking up the challenge of manufacturing the distinctive domed central disc seen on the MIH Gaïa watch.

“The project demonstrates something that is often forgotten: that here in La Chaux-de-Fonds we are in a position to create amazing things with the extraordinary watchmaking expertise of subcontractors that are still family-owned.”

Joris Engisch, director

Jean Singer & Cie

Joris Engisch, director

The MIH Gaïa watch is a quite a unique project. What made you want to be a part of it?

“We wanted to support the MIH by offering our company’s services. This is a great way to mark this milestone together.”

What positive impact do you think this project has as something “made in La Chaux-de-Fonds”?

“It demonstrates something that is often forgotten: that here in La Chaux-de-Fonds we are in a position to create amazing things with the extraordinary watchmaking expertise of subcontractors that are still family-owned.”

Just like the MIH watch, the design of a timepiece is always the result of a collaborative process. What are the differences, difficulties and benefits of working in this way?

“The one and only difficulty per se is to ensure we understand what our clients want and know how to interpret this in technical and aesthetic terms. Once all this is clear, nowadays nothing is impossible. The toughest thing is making choices, since the possibilities are infinite.”

What are the areas of activity, successes and expertise that can be attributed to your company?

“Over the years we have built up a real expertise in new technologies for vapour phase surface treatments, known as PVD. The colours developed by Singer are known far and wide, and have names such as Singer blue no. 5 and Singer blue no. 11. Our competitors also use these names for placing orders. Besides this, the traditional expertise Singer has acquired over the century we have been in business gives us a certain credibility with clients.”

Georges Brodbeck – 50th Anniversary Edition Dial Guilloché

Georges Brodbeck, who began his career as a precision mechanic, entered the world of horology in 1973. Fascinated by the restoration of antique machines and guilloché work, he dedicated himself to this craft in the 1990s, eventually opening his own workshop in 2001. Far more than just a decorative technique, Brodbeck has played a crucial role in reviving an art that seemed forgotten since the 1950s. This master craftsman honored the MIH by lending his virtuosity to the creation of the MIH Gaïa 50th Anniversary Edition’s guilloché patterns.

Georges Brodbeck

Guillocheur

Georges Brodbeck, you are well-known for your mastery of guilloché work as well as your skills in restoring old machines. We’re in your workshop, and there are machines everywhere!

“The oldest machine I have dates back to 1770. Today, I challenge anyone to recreate a machine like that using the tools they had back then. There wouldn’t be anyone smart enough to do it—they were made differently, and they took their time, too.

There’s no such thing as a bad machine, only bad workers. Each one has its own character, its own flaws. You have to compensate. It’s like humans—if we were all perfect…”

The MIH Gaïa watch is a project that breaks new ground. What made you want to participate?

“When the curators of the International Watchmaking Museum presented their idea to me, I was touched by the nobility of the project. I wanted to contribute in my own way to help the museum shine. Each model is unique, requiring special attention. You give a part of yourself to each piece. That’s what I enjoy about it.”

Can you describe some guilloché patterns for us?

“The most classic is the flinqué. These are waves that are successively aligned on top of each other, creating what we call bicycle spokes. The ‘clou de Paris’ is a crossing of two lines at ninety degrees to create small pyramids—that’s very traditional. Then, starting from an initial flinqué design, if you offset the lines, you get flammé flinqué, twisted flinqué, or spiral flinqué.”

And what about the design of the MIH watch?

“The decoration of the MIH Gaïa watch is a succession of lines on a well-defined sector, where there will be random stops and spaces between the lines that vary from one to the next.

Each piece will be completely unique; no two will be the same.”

What were the challenges related to its creation?

“For the MIH watch, you have to be very attentive. I have to control the spaces, the starting points, and the stops, so there’s a focus on each line.

You need to maintain a constant speed as the burin travels through the material and be able to remove it without having already stopped. If you stop while still in the material, the tip of the burin will break, leaving a mark.”

POSITIVE COATING – The Dial Coating for the MIH Gaïa III Series

Founded in 2004 at the heart of the microtechnology industry, POSITIVE COATING specializes in developing innovative solutions in the field of surface treatments. Since 2012, the company has successfully combined PVD (Physical Vapor Deposition) and ALD (Atomic Layer Deposition) technologies to offer stable and uniform coatings while significantly expanding the range of available colors. These treatments, applicable to parts with complex three-dimensional geometries, are used to adorn 100 numbered models of the MIH Gaïa III series watch.

POSITIVE COATING

Ophélie Steinmann, Customer relations and sales

The MIH Gaïa watch is an unconventional project. What inspired you to participate?

As a member of the Friends of the MIH for several years, POSITIVE COATING was immediately captivated by the concept of the MIH Gaïa watch. Partnering with this project for our 20th anniversary creates a bridge between the history and future of watchmaking, blending craftsmanship with cutting-edge technology.

What positive impact does this “made in La-Chaux-de-Fonds” project reflect for you?

Through this project, POSITIVE COATING actively contributes to the local cultural scene and enhances the international reputation of the MIH. This collaboration celebrates the importance of watchmaking and microtechnology in our region.

The MIH Gaïa watch project allows POSITIVE COATING to share its passion with a broader audience, inspire the next generation of watchmakers, and strengthen its commitment to excellence. The company is honored to participate in this initiative and looks forward to presenting its contribution.

Like the MIH watch, the design of a timepiece is always the result of collective effort. What are the challenges, developments, and benefits of this process?

Watchmakers must constantly innovate while respecting the traditional techniques and aesthetics of Haute Horlogerie. Through collaboration among experts, the design of timepieces continually evolves, integrating innovations without compromising artisanal quality. New technologies offer fresh possibilities in design, durability, aesthetics, and performance. POSITIVE COATING leverages these advancements, combines them with technologies from other sectors, and draws inspiration to create cutting-edge decorative and functional coatings.

What are your company’s key areas of expertise, successes, and specialties?

POSITIVE COATING offers a wide range of colors for watch decoration, from monochrome coatings to two-tone treatments and various gradients. In addition to decorative coatings, the company also provides high-performance functional treatments. This expertise has established POSITIVE COATING as a leader in high-quality PVD (Physical Vapor Deposition) and ALD (Atomic Layer Deposition) coatings. The company collaborates with renowned manufacturers and meets the most stringent quality standards.

In 2024, POSITIVE COATING will have been adding color to time for 20 years. Thanks to its innovation-driven strategy, the company proactively introduces next-generation coatings every year.

Brasport – the strap

The company Brasport specialises in leather watch straps, as well as other small leather goods (such as cases, card holders and cigar cases). Brasport was created in 1946 and is committed to innovating in its sector. This partnership therefore gave the MIH the opportunity to combine the MIH Gaïa watch with the highest quality leather.

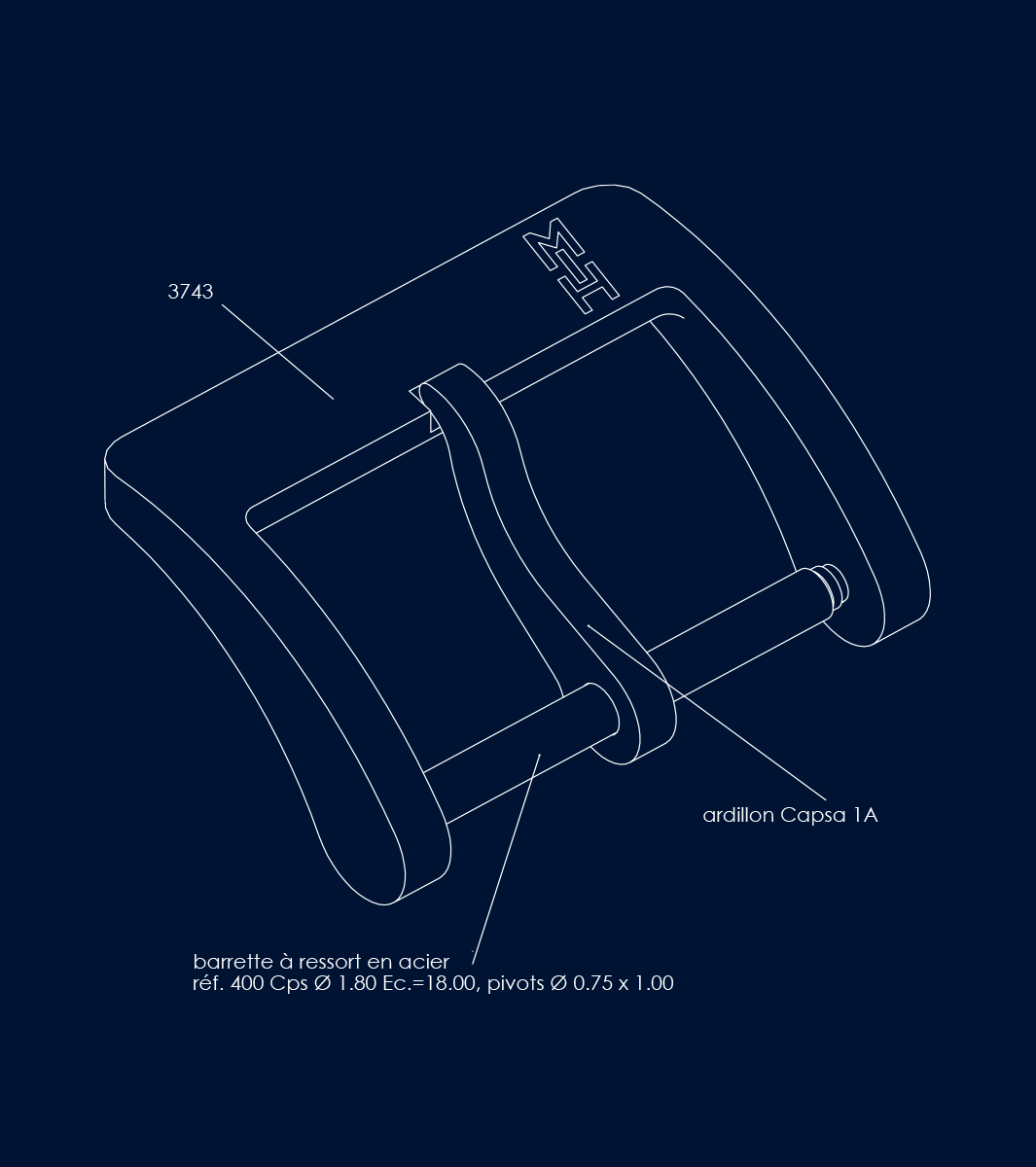

Cornu & Cie – the buckle

Cornu & Cie is a manufacturer specialising in metal straps, folding buckles, clasps and metal tongue buckles – and inventiveness is its watchword. This is a value it shares with the MIH as part of this venture.

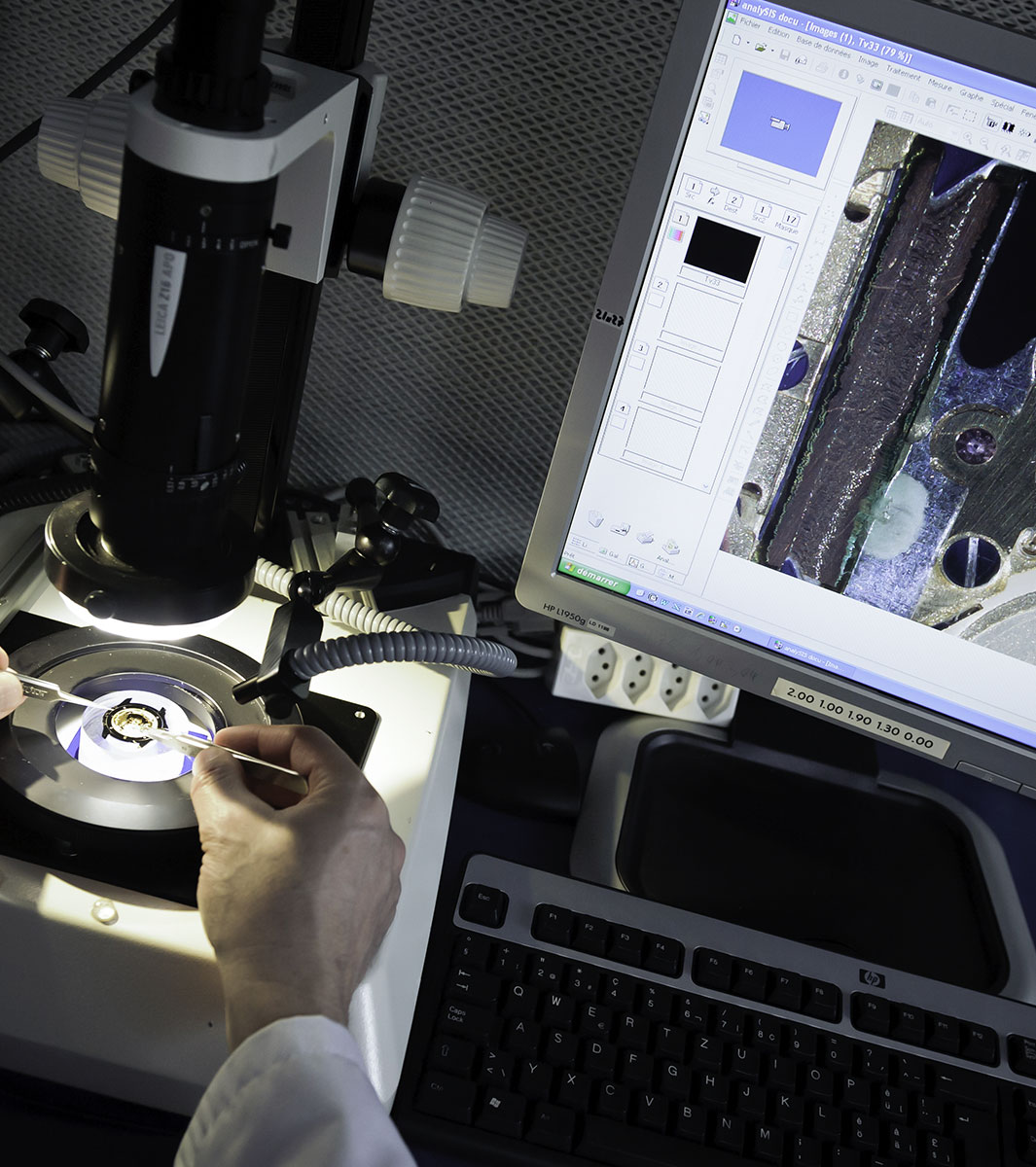

Laboratoire Dubois – the reliability tests

The museum approached Laboratoire Dubois to guarantee precision and compliance with standards the MIH Gaïa is not designed to be kept behind glass but to be worn on a daily basis. The laboratory has specialised in testing, analysis and checks for the watchmaking industry since the 1970s. Incidentally, its founder Henri Dubois won the 2014 Gaïa Prize in the Entrepreneurship category.

”I appreciate the fact that the project involves different local participants from the watchmaking industry; we can each make an individual contribution in our own specialist area. Creating a watch represents the pooling of many different skills and crafts. Here, in the capital of watchmaking, we have all of these assets.”

Patrick Dubois, CEO

Laboratoire Dubois

Patrick Dubois, president

The MIH Gaïa watch is a quite a unique project. What made you want to be a part of it?

“The people who dreamt up the project at MIH had an infectious enthusiasm that made me want to offer the Laboratoire’s services for our area of competence – reliability.”

What positive impact do you think this project has as something “made in La Chaux-de-Fonds”?

“I appreciate the fact that the project involves different local participants from the watchmaking industry; we can each make an individual contribution in our own specialist area. Creating a watch represents the pooling of many different skills and crafts. Here in the capital of watchmaking we have all of these assets.”

Just like the MIH Gaïa watch, the design of a timepiece is always the result of a collaborative process. What are the differences, difficulties and benefits of working in this way?

“Joining forces is very inspiring and requires a great deal of communication; it’s an enriching experience. Of course, this can sometimes bring certain complications into the process.”

What are the areas of activity, successes and expertise that can be attributed to your company?

“We specialise in testing, analysis and checks, whether for movements, exterior or straps. In this context, we provide quality control and reliability testing for watches on behalf of our watchmaking clients. We also operate in